Standard Modular Solutions

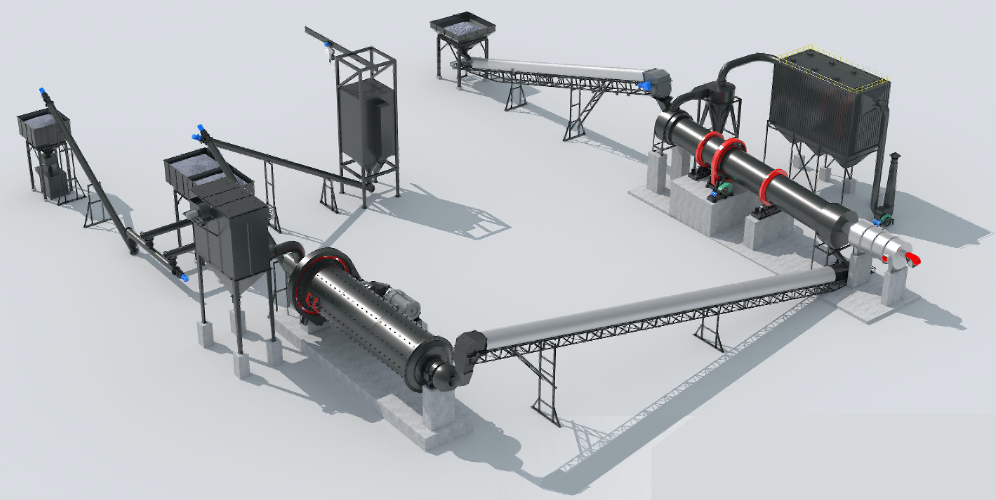

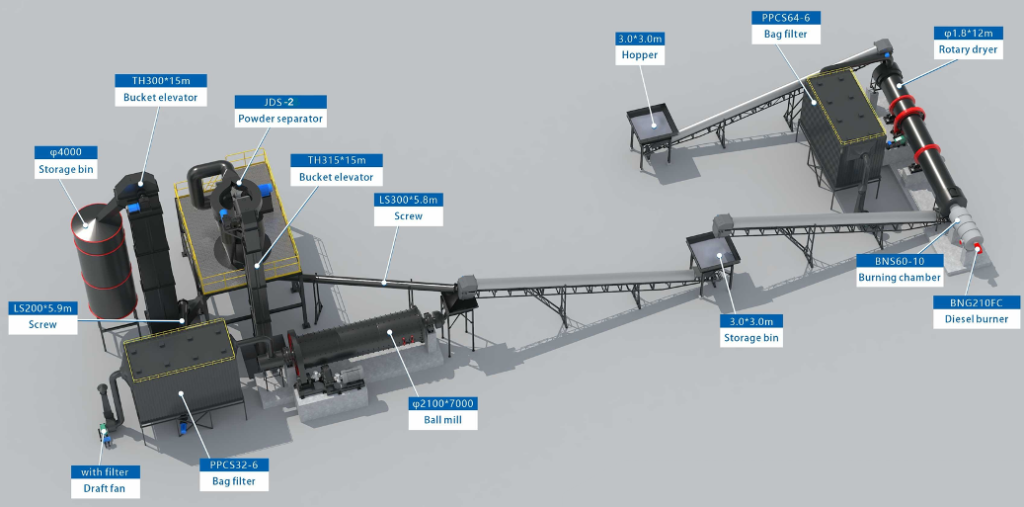

We design plants based on robust, standardised modules that keep costs low and delivery times short. Our offer includes:

- Ball mills from 3 tph (≈ 90 kt/year of CEM IV 42.5 with 25% pozzolana) up to 30 tph, available in open- and closed-circuit modules.

- Rotary dryers capable of treating raw materials with up to 20% moisture.

- Crushing systems for pre-crushing supplementary cementitious materials (SCMs) when required.

- Blending plants for flexible and precise product formulation.

- Bagging machines for a wide range of packing formats.

- Automated big-bag breakers for efficient bulk handling.

- Ball mills up to 6 tph are supplied pre-mounted on a steel chassis, ensuring rapid and accurate installation — without the need for costly civil works.

Customised to your Requirements

Every site and project is different. That’s why we tailor each plant to your environment, seamlessly integrating new modules with existing facilities.

- From simple, cost-efficient installations to fully instrumented plants with advanced sensors.

- From basic dust collection to fully dedusted processes meeting the strictest environmental standards.

- From manual operation to full automation for maximum efficiency and reliability.

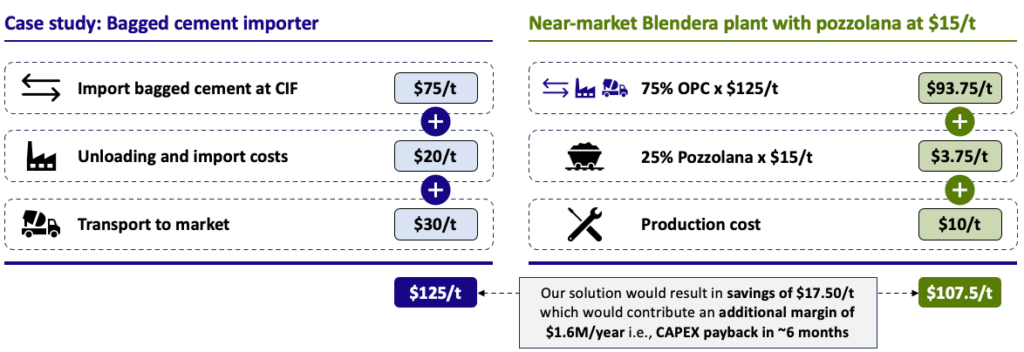

Business Case

A 90 ktpa Pozzolana plant (dryer, 3 tph ball mill, blending and bagging plant) delivers an additional margin of 1.6 mUSD/year!